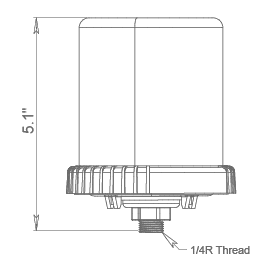

The MEMOLUB® EM is a battery powered, self-contained automatic lubricator designed for the minimal lubricant requirements of electric motors.

Part Numbers:

MLEM120 - MEMOLUB® EM Model 120cc

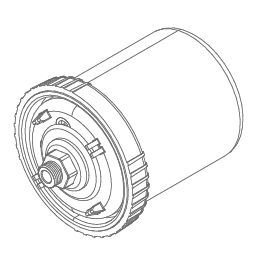

Lubricant cartridges & battery packs sold separately - Click here for information

The MEMOLUB® EM lubricator automatically delivers a small, precise amount of lubricant at regular intervals for an continuous supply of fresh lubricant directly to your lube point. Prevents over and under lubrication problems related with manual lubrication.

All MEMOLUB lubricators are designed with a transparent housing for quick visual inspection of the lubricant level.

Simple Programming

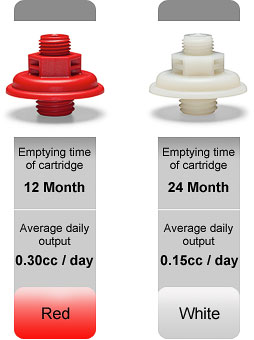

The MEMOLUB® EM daily lubricant output is programmed using the simple colored MEMO system. The Red and White timing MEMOs determine how long it takes to empty the lubricant cartridge.

There are two basic time settings; 12 and 24 month ideally suited for electric motors. Once the appropriate colored MEMO is installed, the program is retained in the MEMO fitting, and at the lube point, allowing the user to interchange other MEMOLUB® EM lubricators without the worry of reprogramming.

Memolub EM is Easy to Install

Grease filled lubricators come preloaded with a lubricant cartridge and battery pack for quick installation. Oil filled lubricators require installation of the lubricant cartridge and battery pack on site.

Product Resources:

How to Order Lubricant Replacement Cartridges .pdfContact us to learn more about the easy-to-use, effective MEMOLUB lubricator.

|

Case Study No. 818 - Rotating Furnace Application: Dryers Industry: Chemical Issue: Oil lubrication dispensed by an inadequate central lubrication system leading to over-lubrication, pollution, wear of the rollers and heavy vibration of the furnace. Solution: Installed MEMOLUB® GIGA lubricators initially set at a 15 day setting. After further inspection the setting was changed to 1 month. After 2 months, wear has been reduced along with furnce vibration. No more spillage and pollution. Shown here are MEMOLUB's protected with plastic bags against the harsh enviroment. |

||

|

|

||

|---|---|---|

| Product Description | Item Number | |

|---|---|---|

|

|

IPMLLBK-2 |

|

|

See MEMOLUB Replacement Kits page |

|

|

IPM-DCSM-1 |

|

|

See Pre-filled Tubing Data Sheet |

|

|

||