The MEMOLUB® MPS-03 (Multi-Point System) is a precise, reliable, and easy to install system that can lubricate 3 lube points with one lubricator.

All of the materials required are available to quickly put your MEMOLUB® HPS lubricator to profitable use in a multi-point application.

Purchase prefilled nylon tubing and make installation as simple as "Plug 'n Lube"

How to order your Multi-Point System .pdf

How to order your Plug 'n Lube pre-filled nylon tubing .pdf

The MPS-03 System consists of a MEMOLUB® high pressure lubricator, a distribution valve which meters the lubricant to all lube points, a mounting bracket and push-in tube fittings for your bearings.

All MEMOLUB® MPS systems have been primed before shipment and are ready for use. On first installation of the MPS system, all lube lines and bearings should be pre-charged with the same lubricant that was ordered with the MEMOLUB® lubricator (prefilled tubing is available and sold separately).

This system is especially suited for applications with several lube points in close proximity.

Grease or Oil:

There are two system types available; one for grease applications and one for oil applications. When ordering, be certain to specify the system appropriate for your application.

Memolub MPS Resouces:

Memolub Multi-Point System Distribution Block Set-up Guide .pdf

Memolub Multi-Point System Technical Data Sheet .pdf

Optional Parts:

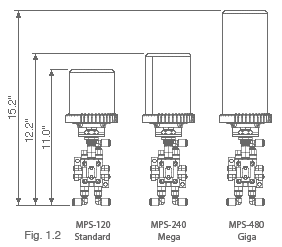

Protective Cover: To protect your MEMOLUB® lubricator in harsher evironments we offer a nylon protective cover. This cover is sold seperately and is available for all three size lubricators.

Prefilled Nylon Tubing: Nylon tubing required to complete the installation is sold separately. The standard size tubing is 5/16” OD, but other sizes are available. Tubing can be purchased two ways; pre-filled in 5 foot increments from 5 to 30 feet, or empty in any length from 1 to 100 feet.

Contact us to learn more about the easy-to-use, effective GREASOMATIC lubricator.

|

Case Study No. 602 Application: General Production Equipment Industry: Cement Issue: Lubrication was done manually, and only when the machine was able to be shut down. Also, cement contamination introduced at the zerks caused seal blockage and the turbine stopped from the resulting pressure build-up. Solution: Two 5-Point MEMOLUB lubrication systems were installed to service all the lube points automatically, at regular intervals. Lubricators were placed in a convenient location so that the lube cartridges could be changed without shutting down the machine. |

||

|

|

||

|---|---|---|

| Product Description | Item Number | |

|---|---|---|

|

|

IPMLLBK-2 |

|

|

See MEMOLUB Replacement Kits page |

|

|

IPM-DCSM-1 |

|

|

See Pre-filled Tubing Data Sheet |

|

|

||