Memolubs are decentralized lubricators for Conveyors, Cranes, Crushers, Pumps, Elevators, Lifts, Trains and Hoists, Industrial Robots, Rollers and Drive Assemblies, Fans and Blowers, Motors and Generators, Chains and Rails, Food Processing Equipment and more!

Memolubs solve lubrication challenges in virtually all industries from Automobile manufacturing to Mining and every thing in between.

Call our helpful Power Lube Industrial staff and we’ll work with you to determine the best lubricator model and offer you many lubricant options for your application. We stock over 200 of the most commonly used lubricants.

Part Numbers:

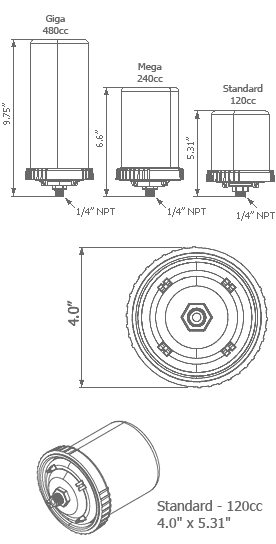

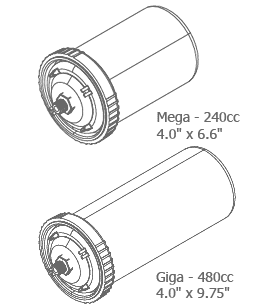

MLHPS120 - MEMOLUB HPS Model 120cc

MLHPS240 - MEMOLUB HPS Model 240cc

MLHPS480 - MEMOLUB HPS Model 480cc

Lubricant cartridges & battery packs sold separately

The MEMOLUB® HPS single point lubricator automatically delivers a small, precise amount of lubricant at regular intervals for an continuous supply of fresh lubricant directly to your lube point. Prevents over and under lubrication problems related to manual lubrication.

All MEMOLUB HPS models use the same motor base assembly, making it easy to convert from one lubricant capacity to another by simply purchasing a low cost transparent housing kit.

Simple MEMO Programming

The MEMOLUB® HPS daily lubricant output is programmed using the simple MEMO system. The MEMO can be programmed to control both the frequency of lube cycles and the volume of lubricant discharged. Once the MEMO is programmed and installed any MEMOLUB® HPS lubricator will recognize the settings.

| Colored timing rings | Strokes per day | CC's per stroke | Daily output in CC's | Model 120 months to empty | Model 240 months to empty | Model 480 months to empty | |

|---|---|---|---|---|---|---|---|

|

R

W

B

|

24 | 0.63 | 15.1 | N/A | 0.5 | 1 | |

|

R

W

|

12 | 0.63 | 7.6 | 0.5 | 1 | 2 | |

|

R

B

|

4 | 0.63 | 2.5 | 1.5 | 3 | 6 | |

|

R

|

2 | 0.63 | 1.3 | 3 | 6 | 12 | |

|

W

B

|

1.5 | 0.63 | 1 | 4 | 8 | 16 | |

|

W

|

1 | 0.63 | 0.6 | 6 | 12 | 24 | |

|

B

|

0.5* | 0.63 | 0.3 | 12 | 24 | N/A | |

| * Lubrication cycles every other day (48 hours) | |||||||

Basic Frequency Settings

There are 7 basic frequency settings that are suitable for most industrial applications. They are programmed by installing one or a combination of the three colored timing rings into the ring holder attached to the brass fitting. When you screw the MEMOLUB® lubricator onto the brass fitting, the timing rings depress the switches on the bottom of the lubricator. This activates the lubricator program.

Adjusting the Volume of Lubricant

Included in the MEMO kit is eight spacer washers for adjusting the amount of lubricant discharged per lube cycle. Installing one, or a combination of all eight washers, into the brass MEMO fitting will limit the stroke length of the piston inside the lubricator.Product Resources:

Contact us to learn more about the easy-to-use, effective MEMOLUB lubricator.

|

Memolub HPS Downloads |

||

|---|---|---|

| ORDERING INFORMATION SHEET - How to order a new Replacement Lubricant Cartridge Kit for your MEMOLUB® lubricator - Power Lube Industrial stocks over 200 lubricants to meet your equipment requirements. Our Lube List is constantly changing so if your lubricant is not listed please give us a call. - Example: To order a lubricant Replacement Kit for a previously purchased MEMOLUB Model 240HPS lubricator filled with Mobilgrease XHP-222, the part number would be: “K4MOBXHP222”. .....Download | ||

| How to order your “Plug ‘n Lube” pre-filled nylon tubing to quickly install your MEMOLUB® lubricator - Power Lube Industrial stocks over 200 lubricants to meet your equipment requirements. Our Lube List is constantly changing so if your lubricant is not listed please give us a call. - Example: To order 20 feet of 5/16” O.D. tubing filled with Mobilgrease XHP-222 the pre-filled nylon tubing the part number would be: “TB5820MOBXHP222”. .....Download | ||

| How to Order a MEMOLUB® High Pressure Lubricator - There are two steps to ordering a new MEMOLUB® lubricator - Step 1: Choose the model and size of the MEMOLUB® lubricator - Step 2: Order the Lubricant Cartridge Kit for the MEMOLUB® lubricator .....Download | ||

| Appvion, a manufacturer of coated papers in Appleton, WI, relies on a system of heaters and air nozzles to dry paper after it’s coated with a substrate In this high-production environment, reliable lubrication of the blower fans that supply the air is a must. .....Download | ||

| MEMOLUB HPS est un graisseur électromécanique, autonome pour point unique ou points multiples. Sa puissance de 25 bars ouvre un tout nouveau champ .....Download | ||

| The MEMOLUB® HPS (High Pressure System) is both an advanced design, highly accurate, single point automatic lubricator and a low cost miniature central lubricating system. It operates as a battery powered self-contained lubricator. Models are also available that use an external 4.5, 12 or 24DC volt power source. MEMOLUB® can operate under its own program control, under control of the machine being lubricated or a PLC. .....Download | ||

| An orthographic projection technical drawing of the Memolub Model 120 - HPS, EPC, EPS, PLCd .....Download | ||

|

|

||

|

Case Study No. 021819 - Lubricating Electric Motor Bearings Application: Motors & Generators Industry: Energy Industry Background: Our customer needed a solution to automatically lubricate the 250 hp electric motors located on the roof top. Issue: Because these motors were in a very high location, the maintenance personnel had to climb several stories to manually lubricate the bearings. Solution: Drive shaft bearing: Installed a single-point MEMOLUB® Mega lubricators filled with Mobil Polyrex EM grease with a change-out setting of 3 months.

Support bearing: Installed a single-point MEMOLUB® HPS Standard filled Mobil Polyrex EM grease with a change-out setting of 3 months. Results: Streamlined their lubrication program and improved workplace safety. Worth Mentioning: Power Lube Industrial recommends the plastic Protective Cover for outdoor applications.

Download this case study. |

||

|

|

||

|---|---|---|

| Product Description | Item Number | |

|---|---|---|

|

|

IPMLLBK-2 |

|

|

See MEMOLUB Replacement Kits page |

|

|

IPM-DCSM-1 |

|

|

See Pre-filled Tubing Data Sheet |

|

|

||